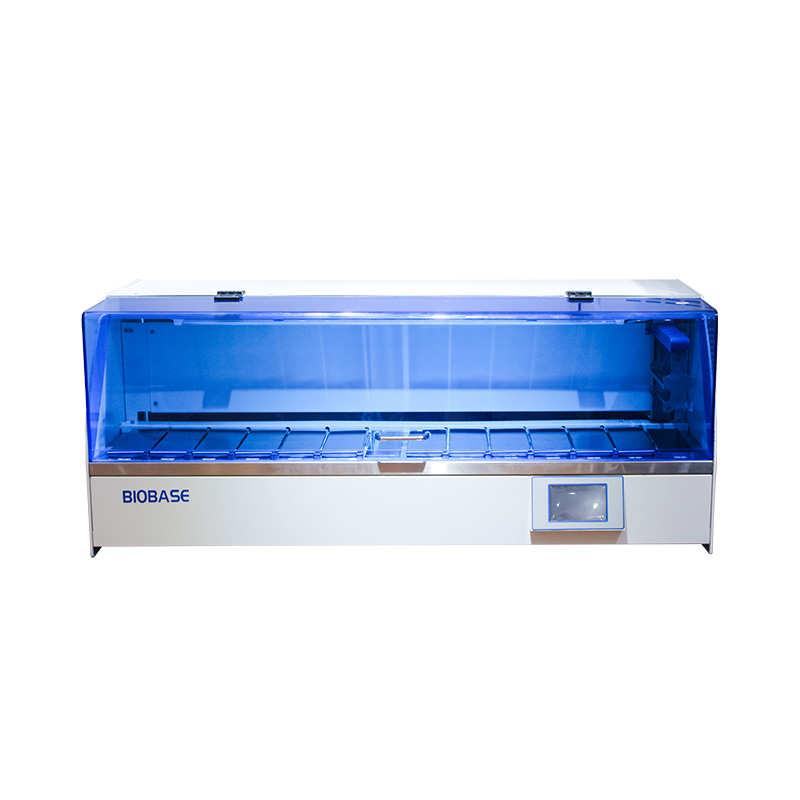

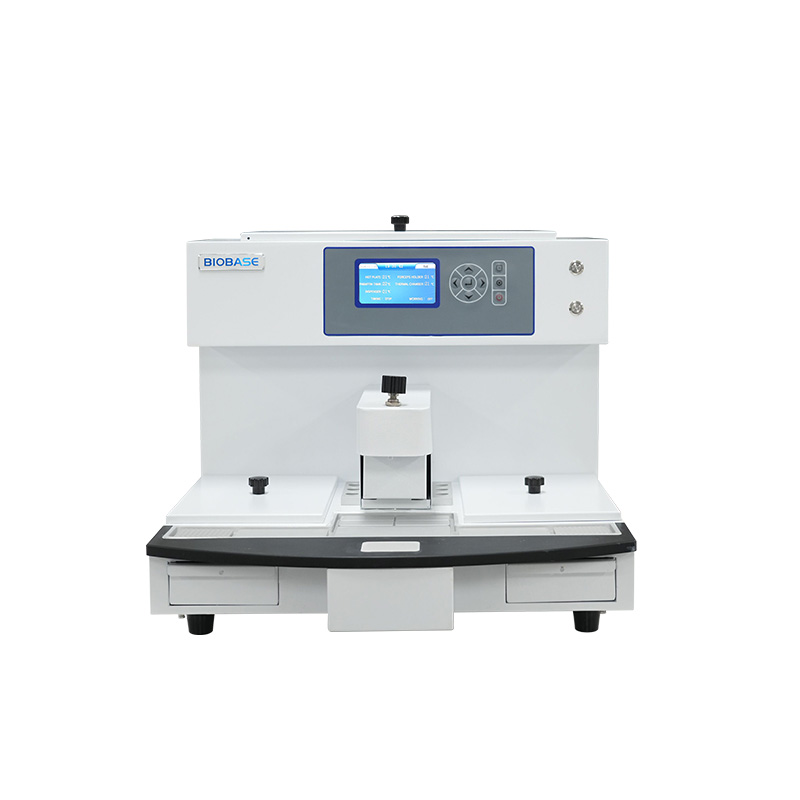

Biological Fermentation System

Brand BIOBASE

Product origin CHINA

Delivery time Within 7 days

Supply capacity Factory Direct Supply

Model BK-BR50 BK-BR100

Introduction:

The Biological Fermentation System is an advanced setup designed for the efficient cultivation of microorganisms, cells, and enzymes for various biotechnological applications. Ideal for research and food industries, this system enables controlled fermentation processes, ensuring optimal growth conditions for yeast, bacteria, and other cell types.

Download

Features:

1. Large color touch screen, simple interface and operation.

2. The peristaltic pump is easy to load, and the 4 fixed-speed peristaltic pumps can be directly used for the control of acid supplementation or alkali supplementation or feeding or defoaming.

3. The entire system is simple to configure, and can quickly enter into fermentation operations or new project research and development, shortening process optimization time.

Technical Parameters:

Model | BK-BR50 | BK-BR100 | |

Tank Structure | Capacity | 50L | 100L |

Sterilization Method | In-place sterilization | ||

Design Pressure | 0.3Mpa | ||

Working Pressure | ≤0.15Mpa | ||

Inner Material | 316 stainless steel | ||

Interface | Air inlet, exhaust port, temperature probe port, PH probe port, DO interface, defoaming interface, flame protection inoculation port, feeding port, discharge port, jacket upper and lower port, etc | ||

Polishing | Internal Polishing Accuracy: RA0.4 External Polishing Accuracy: RA0.6 | ||

Coefficient of Charge | 60%~80% | ||

Aspect Ratio | 1:2~2.5 | ||

Jacket | Design Pressure: 0.3Mpa Material: 304 stainless steel Used for temperature control and auxiliary sterilization. | ||

Intake Filtration | Maximum Ventilation: 1.5VVM, precision 0.01μm sterilization filter | ||

Motor | Power | 1500W | |

Speed | 50~700rpm continuous stable adjustable | ||

Control Accuracy | ±0.5%* Max Speed | ||

Resolution | 1rpm | ||

Stirring System | Top mechanical stirring system, stainless steel with special heat treatment for mixing shaft, adjustable mixing blade is adopted, with six straight blades in 1 gear and inclined blades in 1 gear pressure turbine, the three-stage pressure type efficient defoaming paddle is set up with a baffle plate, and the intake air is set up with a ring distributor, and the gas-liquid two phases are fully mixed to improve the dissolved oxygen | ||

Sterile Air Handling System | Air Pre-filter | Filtration Capacity: 0.1m³/min Accuracy: 0.1μm Membrane Filtration | Filtration Capacity: 0.2m³/min Accuracy: 0.1μm Membrane Filtration |

Air Fine Filter | Filtration Capacity: 0.1m³/min Accuracy: 0.01μm Membrane Filtration | Filtration Capacity: 0.2m³/min Accuracy: 0.01μm Membrane Filtration | |

Steam Filtration System | Stainless steel shell, PTFE filter element, membrane filtration, filtration accuracy is 5μm. | ||

Air Decompression and Oil-water Separator | Reduce the air pressure from the air compressor to 0.2-0.25Mpa, with an oil-water separator to remove oil and water in the air. | ||

Temperature Control System | Measuring Range | 0~150℃ | |

Control Range | Water temperature in tank~65℃ | ||

Control Accuracy | ±0.5℃ | ||

Resolution | 0.1℃ | ||

PH Control System | Control Mode | Automatic | |

Display Range | 0~14PH

| ||

Control Range | 2~12PH | ||

Resolution | 0.01PH | ||

Pressure and Flow Detection Control System | φ60 surface pressure gauge indicates pipe, tank and jacket pressure, manual control tank pressure, measuring range is 0~0.4Mpa;glass rotor flow meter manually control the intake air flow;one-way check valve is added on the pipeline to prevent material back flow from polluting the filter. | ||

DO Control System | Control Mode | Automatic | |

Display Range | 0~100%, 0~150% | ||

Accuracy | ±0.1%, 1% | ||

Testing Content | The DO value is detected online | ||

Feeding System | Manual and automatic control, peristaltic pump flow, equipped with replenishing bottle, the program can set the amount of flow per unit time and accumulate online measurement, equipped with 1L flow refill bottle | ||

Defoaming System | Control Accuracy | 10~100000Ω | |

Control Content | Foam abnormal condition alarm, automatic intermittent processing | ||

Speed Control System | Speed: 50~700rpm±1%, stepless frequency conversion speed regulation | ||

Standard Accessories | Fermentation Tank*1, Air compressor*1, Air tank*1, Steam generator*1 | ||

Power Supply | AC220V, 50/60Hz(Standard); AC110V, 50/60Hz(Optional) | AC380V, 50/60Hz | |

Net Weight | Tank | 185kg | 362kg |

Air Compressor and Steam Generator | 175kg | 214kg | |

Package Size(L*W*H) | Tank | 1350*820*1750mm | 1520*820*2230mm |

Air Compressor and Steam Generator | 1350*1100*1100mm | 1370*1170*1130mm | |

Gross Weight | Tank | 210kg | 392kg |

Air Compressor and Steam Generator | 200kg | 244kg | |