-

Hotplate Magnetic Stirrer BK-MS280 BK-MS340

Introduction: The Hotplate Magnetic Stirrer is a versatile laboratory instrument designed for simultaneous heating and stirring of liquids in various scientific and industrial applications. Ideal for chemical reactions, sample preparation, and temperature-sensitive procedures, this device combines precise temperature control with effective stirring capabilities, ensuring uniform mixing and consistent results.

Send Email Details -

Magnetic Stirrer MS Series

Introduction: Its precise control and user-friendly design help ensure reliable and reproducible results in sample preparation and chemical reactions.

Send Email Details -

Tissue Grinding Machine

Introduction: Tissue Grinding Machine can extract and purify original DNA, RNA, and proteins from any source, including soil, plant and animal tissues/organs, bacteria, yeast, fungi, spores, paleontological specimens, etc. It completes the grinding, crushing, mixing, and cell wall disruption of samples in a very short time.

Send Email Details -

Table Top Large Capacity Shaker-BJPX-SZ10

Application: BJPX-SZ10 is often used in liquid shaking, culture of microorganisms, bacteria and cells and other tests.

Send Email Details -

Table Top Small Capacity Shaker BJPX-SZ11

Application: Suitable for food processing, bacterial culture, agriculture and forestry institutes, etc.

Send Email Details -

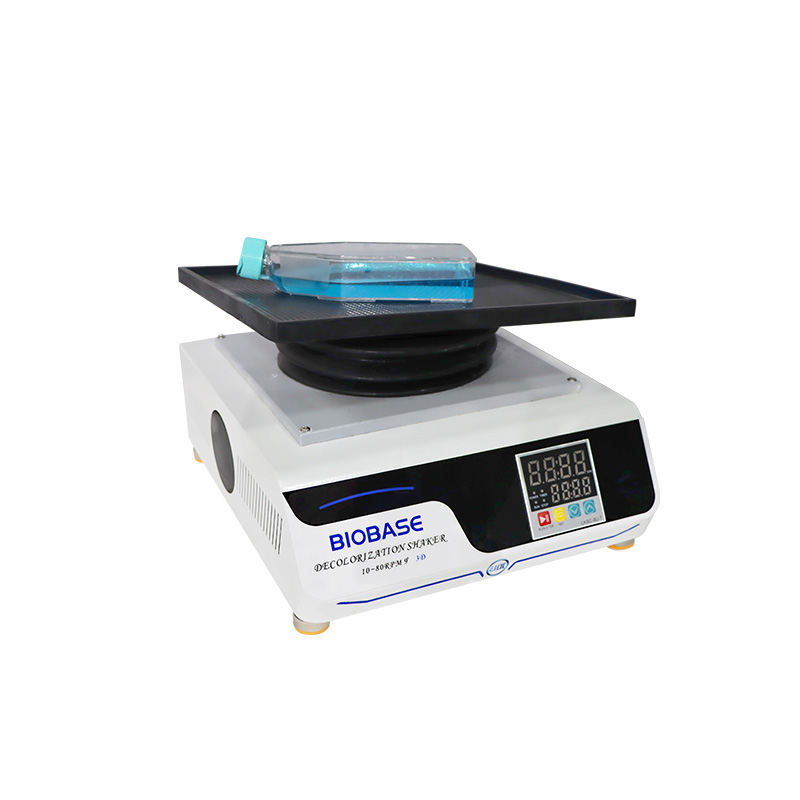

Decolorization Shaker SK-D700 SK-R800 SK-O900 SK-L108

Introduction: Decolorization shaker is widely used for the fixation of electrophoresis gel separation band, the oscillations of Coomassie blue staining and decolorization, the fixation, staining, development of silver nitrate staining, the development and fixing of X-ray film in the autoradiography experiment, further processing of cellulose film after electrophoretic transfer, the reaction and staining of antigen, molecular hybridization and cell culture, etc. The decolorizing shaker can be used in any experiment where the sample needs to be shaken in the solution. It can be used in environmental monitoring, medical health, petrochemical, food, metallurgy, PCR laboratory preparation and preparation. It is suitable for laboratories of various colleges and universities, scientific research and production enterprises.

Send Email Details -

3D and Rocking Shaker

Introduction: The 3D and Rocking Shaker is a versatile laboratory instrument designed for gentle yet efficient mixing of samples in research, medical, and industrial applications. This shaker provides three-dimensional motion and rocking movement, making it ideal for staining, washing, hybridization, and general mixing tasks.

Send Email Details -

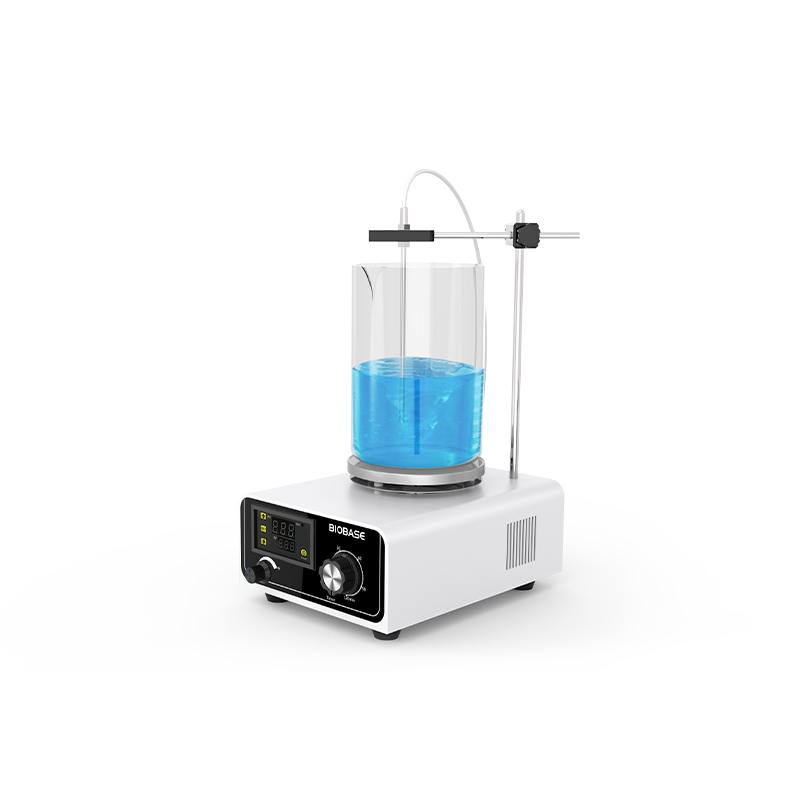

Hotplate Magnetic Stirrer BK-MS120

Introduction: Hotplate Magnetic Stirrer has high sensitivity, strong controllability and wide temperature control range. It is suitable for liquid or solid liquid mixtures with low viscosity that need to be stirred or heated and stirred at the same time. With the temperature control device, it can control and maintain the sample temperature according to the specific experimental requirements, help the experimenter set the experimental conditions, which greatly improve the possibility of experimental repeatability. It is widely used in colleges, research institutions, chemical industry and other fields.

Send Email Details -

Manifolds Vacuum Filtration

Introduction: Manifolds Vacuum Filtration is a kind of basic equipment for solid liquid separation by producing pressure difference through negative pressure vacuum suction pump. The main principle is to extract the air inside the filter device through the suction pump, forming an obvious pressure difference, so that the external atmospheric pressure pushes the liquid to be filtered through the microporous filtration membrane, to achieve the purpose of solid-liquid separation .

Send Email Details -

Optional shaker accessories

Introduction: Enhance the versatility and functionality of your laboratory shakers with our range of Optional Shaker Accessories. Designed to fit seamlessly with a variety of shaker models, these accessories allow you to customize your equipment to meet specific experimental needs, ensuring optimal performance and efficiency in your lab.

Send Email Details -

Table Top Small Capacity Shaker

Applications: It is widely used in bacterial culture, fermentation, hybridization, biochemical reaction, enzyme and cell tissue research. It has extensive and major applications in research and application fields such as biology, molecular science, food, and environment.

Send Email Details -

Table Top Large Capacity Shaker SK-852

Applications: It is widely used in bacterial culture, fermentation, hybridization, biochemical reaction, enzyme and cell tissue research. It has extensive and major applications in research and application fields such as biology, molecular science, food, and environment.

Send Email Details