Buyer's Guide PCR Technology

Polymerase chain reaction (PCR) technology is a staple of countless research and testing labs, in a range of fields including biomedicine, clinical diagnostics, food microbiology testing and criminal forensics. This fundamental technology uses thermal cycling to facilitate a series of reactions in which a DNA sample is rapidly, exponentially replicated to produce millions or billions of copies of sequence. When acquiring a new PCR system, it is important to consider the end goals of your application, the accuracy and efficiency of the thermal cycling equipment and capacity and flexibility of the instrument. This article gives an overview of different options and features available for PCR systems to help narrow down a suitable system for your application.

1. PCR vs. qPCR vs. dPCR

While all PCR systems replicate DNA using the polymerase chain reaction, there are differing methodologies used by different systems to achieve specific results. Among these differing methods are standard PCR, quantitative PCR (qPCR) and digital PCR (dPCR).

Standard PCR machines are typically used to amplify DNA for further downstream testing and use; in a sense this technology is used as a means to generate an end product rather than as an analytical testing method itself. The amplified DNA can be measured only after the PCR reaction if complete, rather than in real time, and therefore this method is sometimes referred to as end-point PCR. The end product of traditional PCR amplification is commonly used for downstream cloning and sequencing, and can also be checked using gel electrophoresis to confirm the presence of target sequences and their relative quantity at low resolution (based on band intensity).

For more rapid and accurate quantification of the amount of target sequence present in a sample, quantitative PCR (qPCR), also known as real-time PCR, uses fluorescent probes during the amplification process to monitor the amount of DNA present after each thermal cycle. By observing how many cycles are needed to meet a certain threshold of fluorescence intensity, the analyst can determine the amount of DNA in the starting material when comparing results to a standard curve. qPCR can also confirm the presence or absence of a target sequence more quickly than end-point PCR, and thus is used in diagnostic applications such as the detection of SARS-CoV-2 (using reverse transcription to first convert viral RNA to cDNA).

Digital PCR (dPCR) is another quantitative method in which PCR reactions take place in thousands of separate reaction chambers, and the absolute number of DNA molecules in the original sample can be determined based on how many reaction chambers yield a fluorescent signal after amplification is complete. Unlike with qPCR, fluorescent measurements are not performed in real time and a standard curve is not needed to quantify the DNA in the sample. While dPCR typically comes with limited throughput and higher costs than qPCR, it is more precise, sensitive and accurate in quantifying DNA and is especially useful in applications such as the detection of rare mutations and single nucleotide polymorphisms (SNPs).

The determination of whether to choose end-point (qualitative/semi-quantitative) PCR versus a quantitative (qPCR or dPCR) method is relatively straightforward when you consider your application, but the choice between qPCR and dPCR may be more nuanced. qPCR is high-throughput, cost-effective and sufficiently sensitive for many applications, but dPCR may be a better choice if absolute quantification with low detection limits is paramount..

2. The Importance of Temperature Control

The ability of thermal cyclers to accurately and efficiently adjust and control the temperature of samples is what enables the success of amplification reactions and should be a central focus of selecting any PCR system. Different systems may offer different capabilities with regard to ramp rates, temperature uniformity and accuracy, and the ability to achieve temperature gradients across thermal blocks to aid PCR method optimization.

Ramp rate refers to the speed of the temperature changes between thermal cycling steps and is typically expressed as degrees Celsius per second (°C/sec) in instrument specifications. Manufacturers may provide information on maximum ramp rates and average ramp rates as well as differentiate between up the ramp rates (heating) and down ramp rates (cooling) of an instrument. In general, higher ramp rates correspond to faster runtimes, but buyers should be wary about focusing on maximum ramp rates without examining other metrics related to instrument speed. An instrument may only achieve its highest ramp rate for a short amount of time, and the average ramp rate will better reflect the pace of temperature changes. While ramp rate specifications may give a general idea of how fast certain instruments can run, when possible, look for data on actual runtimes demonstrated on an instrument to get a realistic picture of how high ramp rates translate to rapid analyses.

Temperature accuracy and uniformity are also key for successful reactions and while all thermal cyclers are designed to produce the temperatures necessary for PCR, certain features can offer a higher degree of confidence, which is critical for applications in which samples may be limited and reliable results are paramount such as in clinical diagnostics and forensics. Precise temperature control is also crucial when using the PCR machine for sensitive techniques such as high resolution melting (HRM) analysis. A heated lid can ensure better temperature uniformity throughout the PCR tube, as without a heated lid, the sample can evaporate and condense to the top of the tube where the temperature is cooler. Thermal block design also impacts temperature control; aluminum blocks are the most economical option but are the least conductive, meaning they will achieve temperature uniformity more slowly and have lower ramp rates than more conductive blocks. Silver and gold-coated blocks are more expensive but allow heat transfer to occur more rapidly, ensuring even temperature distribution across the block.

Different DNA targets can require different temperatures to achieve the best amplification results; for example, GC-rich sequences need higher temperatures for denaturation. Ideal annealing temperatures are also impacted by a range of factors – while temperatures for this step are usually selected based on the melting temperatures of the primers, differences in melting temperatures between primer pairs, and the influence of reagent concentration, pH and salt concentration can all make optimizing reaction temperature conditions a complicated task.PCR machines with temperature gradient abilities are designed to assist in the optimization of PCR methods by allowing multiple annealing temperatures to be tested in a single run. Depending on the types and the diversity of samples you plan to analyze using your PCR machine, choosing an instrument with gradient capabilities may be worth the additional cost to save significant time and reagent optimizing new protocols in fewer runs.

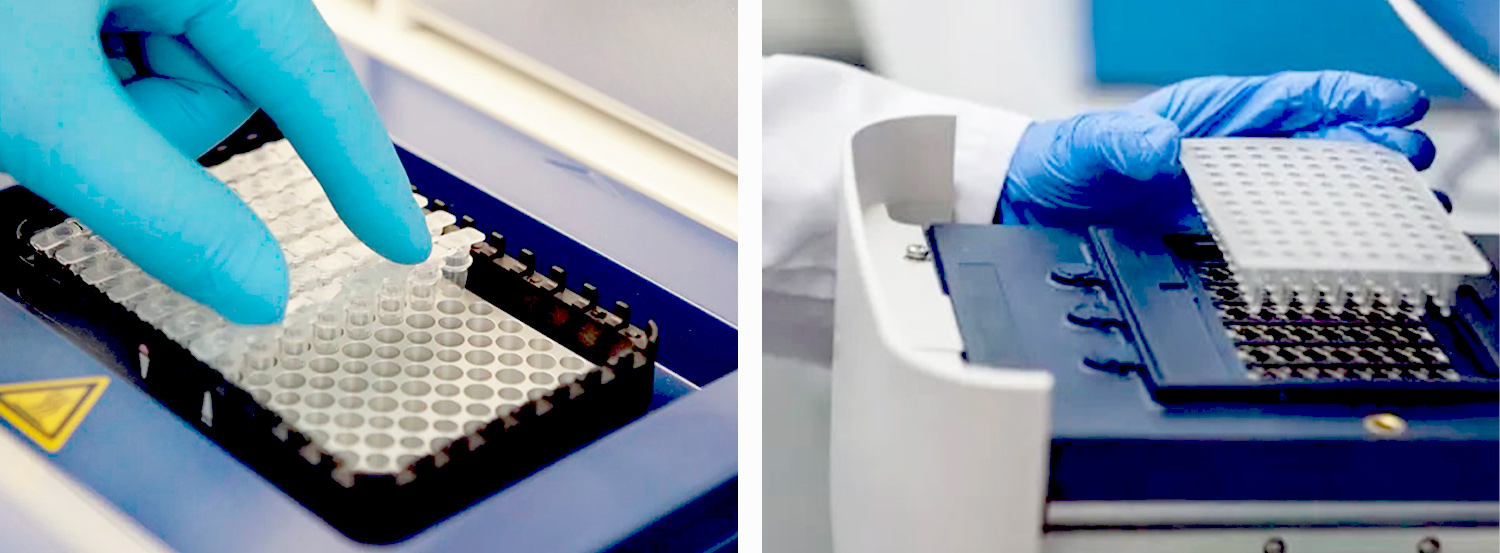

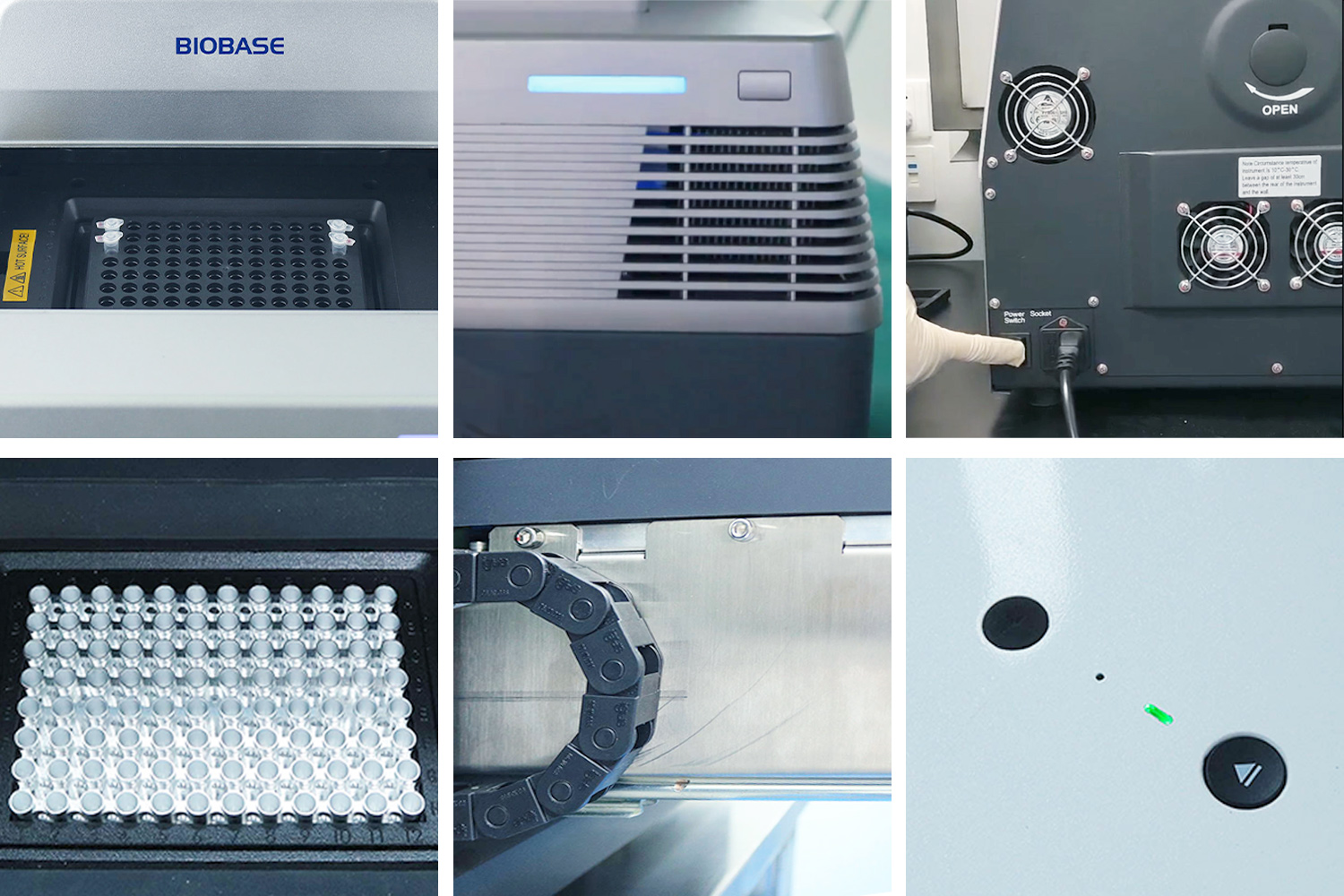

3. Thermal Blocks

As mentioned, the thermal block used with a PCR instrument can make a difference in temperature control, but the block’s design – and the instrument’s design to accommodate different blocks – also impacts throughput, consumable costs and flexibility. Typical blocks will come in a 96-well or 384-well format, although other formats such as 48-well and 1536-well are also available. A higher well count enables higher throughput with lower reaction volumes, which will initially be more costly but ultimately lowers the price per reaction due to the lower volume of reagent used for each well. Considering how many samples you will be processing and how often you will use the machine will factor into whether a lower or higher well-count thermal block will be most practical and cost effective for your laboratory.

Some instruments come with a fixed block format while others allow for interchangeable blocks to be used, offering more flexibility to switch between 96- and 384-well formats or between different block materials for different applications. Some thermal cyclers also accommodate several blocks in the same instrument, enabling different protocols to be run on different sets of samples at the same time.3 Blocks with “universal” dimensions further enhance flexibility to use different size tubes, strips or PCR plates as needed.

Because of this component’s key role in temperature control, sample handling and throughput, the thermal block options should be carefully considered when selecting a thermal cycler. For labs with a low volume of samples, or those routinely running only a handful of assays, lower-cost fixed block instruments with a standard 96-well format may suffice. However, modular, flexible instruments may be advantageous for labs with a greater number of protocols, varying sample volumes and more users relying on the same instrument for their own assays, as well as labs that may want to expand their throughput capacity in the future.